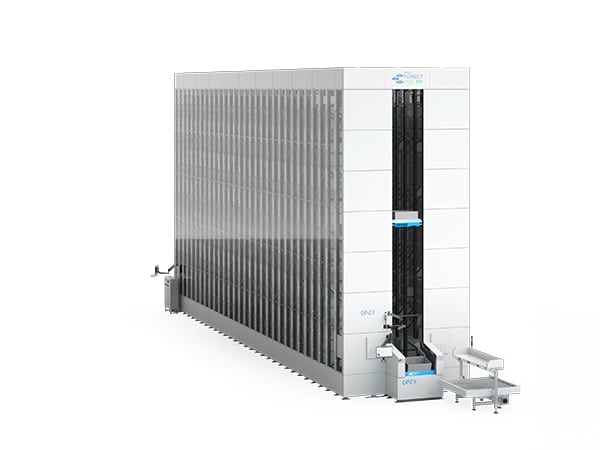

Multishuttle Goods to Person System

Perfect Pick is the Goods to Person system that revolutionises the work of preparing shipments.

Perfect Pick is made up of an automated vertical buffer for crates and/or trays, automated through the use of independent wireless iBOT robots.

It is the most efficient GTP system compared to other multishuttle, miniload, and cubic storage systems.

Perfect Pick by Trascar is available in two standard models: single depth and double depth.

Perfect Pick technology

Balancing the system is very simple because all the iBOTs are able to pick up and deposit all the boxes in every location of the corridor.

The reliability of the system is very high because it can operate even with some iBOTs under maintenance and there are no bottlenecks (elevators).

The scalability of the system is high because it is possible to add or remove iBOTs based on the performance you want to achieve.

The availability of the system is high because it is possible to perform maintenance on the iBOTs offline from production.

The system’s capacity is high because the handling corridor is very narrow and the arrangement of the boxes is intensive.

Our WMCS (for the management of automated warehouses) autonomously decides, based on the quantities of product to be introduced, in which box to insert the products.

It independently manages the choice of storage location, implementing the following logics: distribution of products in the aisles, use of ABC product rotation classes, distribution of empty boxes in the aisles, workload balancing across the various storage aisles.

The WMCS receives the orders to be fulfilled, in terms of item and quantity, from the client’s management system. Based on this, it chooses from which boxes to pick, committing the goods contained in them. Available logics: FIFO, FEFO, LIFO, LEFO, Specific lot.

The WMCS dynamically assigns orders to picking bays in order to balance the workload of the operators.

The WMCS guides the picking operator both in the picking and putting steps. The latter is facilitated with the use of a Pick To Light system.

The freedom to choose boxes, trays, boxes with dividers

The units moved and stored within the Perfect Pick (WLU) can be:

- Single compartment plastic boxes or with dividers up to 8 compartments;

- Plastic trays carrying parcels and/or product packages. The maximum weight of the WLU is 36kg.

The basic sizes of boxes and trays are always the same.

The heights of the boxes vary according to the need (see technical data sheet). Maximum WLU height: 40cm.

The different types of WLU can be managed simultaneously in the individual Perfect-Pick.