Automated logistics for fabric rolls

The products that are handled in rolls include a wide range of industrial sectors.

In its range for AUTOMATED LOGISTICS OF FABRIC ROLLS Trascar offers solutions for all stages of roll preparation, from unloading from the winder to shipping.

UNLOADING WINDERS/CUTTERS

The automation of unloading newly-produced fabric rolls is carried out using systems designed according to the machine in question. The type of product, weight, and diameter are the variables to consider for the automation of the unloading phase.

Anthropomorphic robots, cartesian robots, and automated shuttles (AMR and AGV) managed by the line supervisor reduce the presence of the operator in all machine operation stages.

HANDLING AND LABELLING

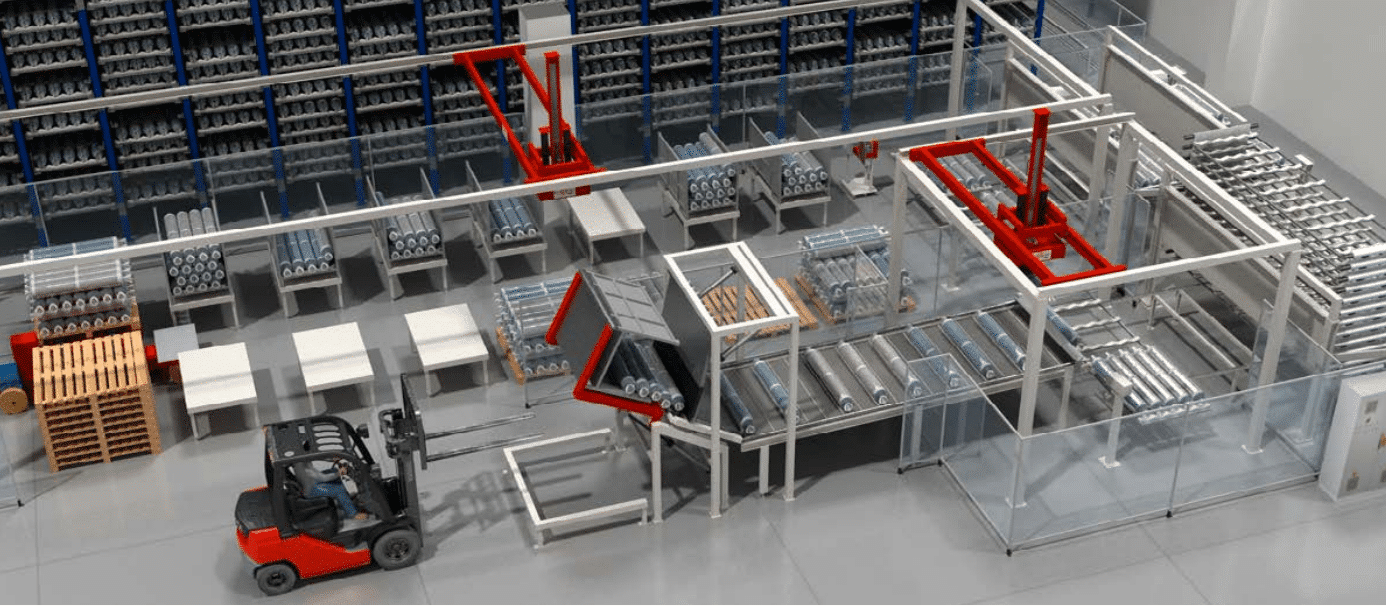

In the logistics of shipping the roll of fabric, handling the package requires particular care to avoid damaging the product and to preserve its cleanliness. This operation is carried out using conveyors of various types, which, depending on the characteristics of the roll being moved, protect it until it is shipped.

The package is labelled in full compliance with the requirements of care and protection of the value of the product being processed; the operation can be performed simultaneously both on the outer film and inside the tube to ensure traceability during shipping.

PACKAGING AND PALLETISING

The end-use requirements of the processed film have greatly differentiated the type of packaging required for the roll in preparation.

Even the final palletising is influenced by the type of packaging applied to the product. There are rolls that are palletised directly without packaging and others that undergo double packaging to avoid contamination in the final use.

Trascar is the reliable partner in analysing client specifications to propose the ideal solution for the automation needs of every manufacturer or converter of plastic, paper, metal, or textile films.

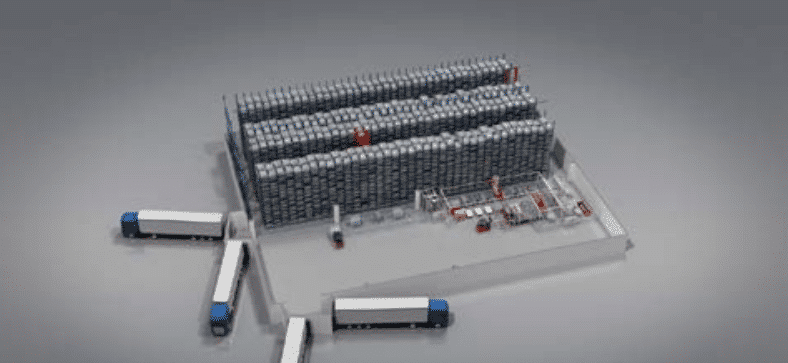

Storage Smart solutions by Trascar

It is the flexible and modular solution that adapts to changing production needs, capable of expanding or reducing storage space according to your needs.

The textile industry involves a wide range of activities, from initial production to distribution and processing. Storage Smart was designed to meet all these needs.

Automated warehouse management is essential to ensure efficiency and accuracy in operations. The warehouse is physically and logically integrated with all stakeholders of the system, facilitating seamless communication between the different stages of the process.

Storage Smart is designed to be a “standard product”, making it accessible to a wide range of clients, including textile manufacturers, fabric roll distributors, raw fabric processing companies, fashion industries, and roll wholesalers.

Storage Smart is the cutting-edge solution that meets the evolving needs of the textile industry.

MAIN TECHNICAL FEATURES

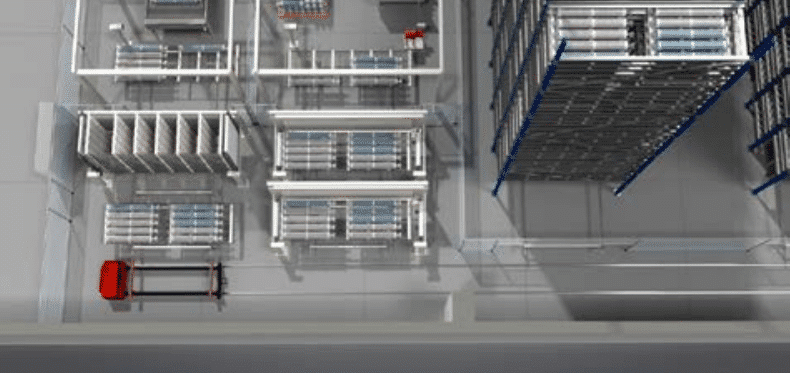

Stacker crane/shuttle system: the Storage Smart solution uses a stacker crane and specialised shuttle systems equipped with the necessary devices for the precise and efficient retrieval, release, and movement of fabric rolls. This system is designed to offer remarkable performance.

The heart of the movement system is the integrated programmable logic controller (PLC) responsible for control and automation. This PLC is connected to a local operator panel (Op Panel), making it possible to monitor and control of warehouse operations in real time. Additionally, the system features a warehouse management software (WMS) for continuous operational management, including item control, inventory monitoring, mapping, historical data, and alert notifications.

The Storage Smart fabric roll warehouse is designed with integration in mind. It can seamlessly connect to the ERP (Enterprise Resource Planning) system for comprehensive business management.

This ensures that data and inventory synchronisation within the organisation happens effortlessly.

From a functional point of view, the system is highly adaptable and can interact with intelligent automated guided vehicles (AMR and AGV). This ability allows coordination with the Trascar AUTOMATED ROLLS WAGON system. These vehicles can autonomously pick up fabric rolls from the warehouse head and transport them to the relevant operational areas, serving cutting, printing, inspection machines, and more with the necessary fabric rolls.

JUMBO SYSTEM

Are you looking for a fabric roll storage system that perfectly fits your specific needs?

JUMBO SYSTEM is the tailor-made automated solution that guarantees unprecedented performance, flexibility, and efficiency for the storage and handling of fabric rolls.

No two companies are alike, which is why Trascar designs tailor-made solutions to the exact dimensions required, ensuring efficient use of your facilities. JUMBO SYSTEM is the system without limitations in terms of height, width, and length, for fabric roll storage warehouses. Whether a compact space or an imposing structure, thanks to self-supporting shelving, Trascar builds warehouses that exceed 30 metres in height.

Our solutions are equipped with custom devices to handle both single rolls and multi-roll trays with precision.

We go beyond simple storage. Our systems are designed for full integration and connect every aspect of your workflow. From loading and unloading containers to inventory management, we cover the entire supply chain.

JUMBO SYSTEM integrates seamlessly with processing machines, such as film winders, printing devices, quality control equipment, cutters, and palletisers. We offer a range of material handling systems, including belt conveyors, roller conveyors, chain conveyors, shuttles, or modern AMR and AGV systems dedicated to roller transport.

We are not just a service provider; we are your partner. Your success is our success and we are committed to working side by side to achieve your goals together.