Trascar is the world leader in the field of automation for the textile industry

With the acquisition of U.T.I.T. in 2023, the world leader in the field of automation for the textile industries, Trascar has consolidated its leadership in the textile industry. As a result, in 2015, a business unit dedicated to high-quality and textile automation services was established.

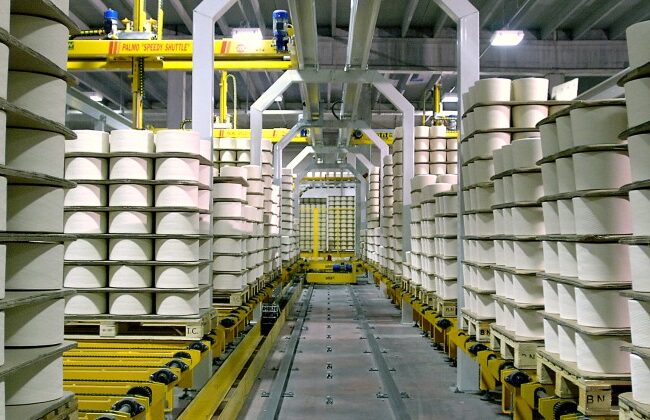

Trascar offers a wide range of solutions for the textile industry, including bobbin and cone transport systems, palletising, packaging and automatic warehouses. Some examples:

Automatic bobbin transport > Trascar’s automatic bobbin transport system is designed to ensure the smoothest transfer of the bobbins from the bench to the spinning area. This system runs in the aisles between the spinning machines and integrates with the desks ensuring maximum automation. It can be adapted to specific customer requirements from manual to fully automatic.

Bobbin tube cleaning > The bobbin tube cleaning system is integrated in the bobbin transports. During cleaning, this system removes the hose from the brush holder, preventing wear on the brush holder and ensuring thorough cleaning.

Contact us today to learn how we can improve your textile production!